As a forward-thinking provider, you want to be confident in providing the best possible treatments for your patients. To do that, you need to understand the clinical efficacy and latest innovations in wound care technology. At Tides Medical, advanced regenerative medicine products are no longer a futuristic ideal.

Introducing APLICOR 3D, a single-use 3D-printed graft for the treatment of chronic wounds. The APLICOR 3D system allows surgical teams to address chronic wounds by printing personalized grafts with patients’ adipose tissue.

In the rapidly advancing world of medical technology, APLICOR 3D stands at the forefront, offering groundbreaking innovations in wound care. This hyper-personalized tissue regeneration platform is transforming how chronic wounds are treated, creating a more efficient process for patients and providers alike.

What is APLICOR 3D?

APLICOR 3D is a state-of-the-art platform that uses the patient’s adipose tissue (fat) to print a personalized graft tailored to fit their wound’s exact size and depth. This single-use, 3D-printed graft aids in treating chronic wounds, including diabetic foot ulcers, venous stasis ulcers, pressure ulcers, MOHs Procedures, burns, and trauma injuries. With over 100 successful cases, the platform is predicted to be a game-changer in personalized medicine.

How Does It Work?

The APLICOR 3D process is straightforward yet revolutionary:

- Wound Preparation: First, debride the wound to ensure it is clean and ready for treatment.

- Wound Measurement: A specially calibrated AiD Regen Tablet captures the size and depth of the wound. This data is then processed to determine the precise amount of fat required for the graft. Simply put, you take a photo of the patient’s wound with the specially calibrated AiD Regen Tablet, and the device creates a 3D file for the printer to read.

- Fat Harvesting: Adipose tissue is extracted from the patient and processed into “bio-ink” using advanced micronization technology.

- 3D Printing: The “bio-ink” is fed into the APLICOR 3D printer, which creates a personalized graft perfectly sized for the patient’s wound.

- Application: The graft is applied to the wound, initiating treatment.

Critical Benefits of APLICOR 3D

Personalized Care: Using the patient’s tissue minimizes the risk of rejection.

Efficient Treatment: The entire process, from fat harvesting to graft application, takes about 60 minutes, saving valuable time in the operating room.

Clinical Success: Over 100 patients have benefited from APLICOR 3D, with case studies showing significant tissue regeneration progression within four weeks.

Cost-Effective: APLICOR 3D also helps lower healthcare costs by reducing the number of procedures and minimizing the complexity of wound management.

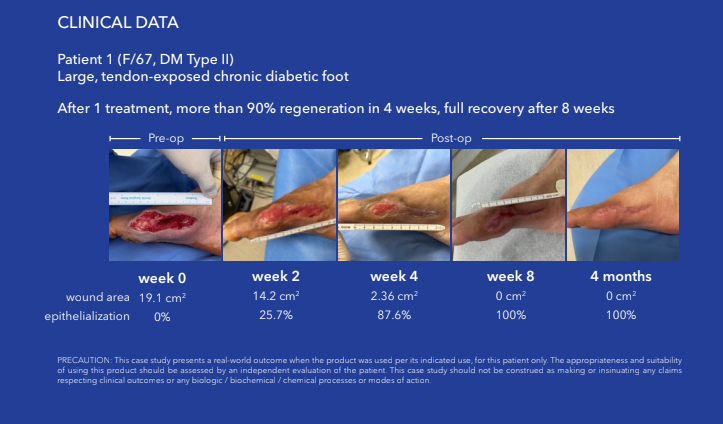

Real-World Impact: A Case Study

A 67-year-old female patient with Type II Diabetes presented with a chronic diabetic foot ulcer that exposed the tendon. After just one treatment with APLICOR 3D, the patient experienced over 90% regeneration in four weeks and full recovery after eight weeks. This remarkable case is just one of many demonstrating the platform’s effectiveness.

Be Part of the Future of Wound Care

The future of wound care is here, and with APLICOR 3D, you can offer your patients cutting-edge, personalized treatment today.

Take advantage of the opportunity to bring personalized power to your practice. Contact us today to learn how APLICOR 3D can revolutionize your approach to wound care.

Marc Stemler, Ph.D.,

Marc Stemler, Ph.D.,  Mora Melican, Ph.D., VP of Operations, Research & Development

Mora Melican, Ph.D., VP of Operations, Research & Development LESA CATALON,

LESA CATALON, DAVID CASTILLE,

DAVID CASTILLE,

Dr. Thomas E. Serena MD FACS FACHM MAPWCA

Dr. Thomas E. Serena MD FACS FACHM MAPWCA JOSH WILLETT,

JOSH WILLETT, JEFF MONTGOMERY,

JEFF MONTGOMERY, MIKE RIDDLE,

MIKE RIDDLE, BENJAMIN KIMBALL,

BENJAMIN KIMBALL, DOUG PAYNE,

DOUG PAYNE, JOE SPELL,

CEO

JOE SPELL,

CEO