3D bioprinting has emerged as a groundbreaking technology in medical innovation, offering revolutionary solutions in regenerative medicine and personalized healthcare.

Bio-ink is crucial in this advancement as a unique material for printing cells, tissues, and even entire organs. Researchers create bio-ink from various biological substances (natural, synthetic, or a combination), and fat harvesting has emerged as a promising method for producing bio-ink for skin grafts.

This blog will dive into fat harvesting and its role in bioprinting, especially in customized skin grafts for wound healing.

What is Bio-Ink?

Bio-ink is a critical component in 3D bioprinting. The “ink” carries living cells and other biomaterials, which are printed layer by layer to create functional tissues. Bio-ink is typically composed of cells derived from the patient’s body for applications like skin grafts, providing a biocompatible material that minimizes the risk of rejection.

Fat tissue is one of the most accessible and rich sources of cells for bio-ink.

Fat-derived cells are beneficial because the fat is easily accessible and can be harvested in sufficient quantities with minimal impact on the donor. Moreover, the cells in fat tissue have proven highly effective for creating bio-ink for skin grafts, offering a faster and more efficient way to produce customized skin solutions for patients.

The Fat Harvesting Process with APLICOR 3D

Fat harvesting is a minimally invasive procedure where fat is extracted from areas like the abdomen, thighs, or buttocks. Soft tissue areas such as the abdomen and inner thighs are the easiest to work with, but other areas of the body also work.

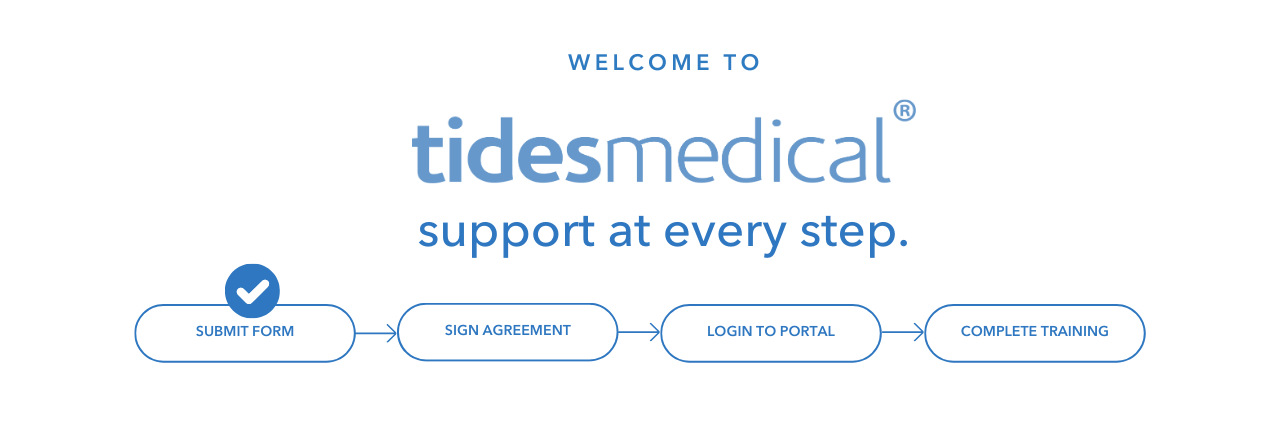

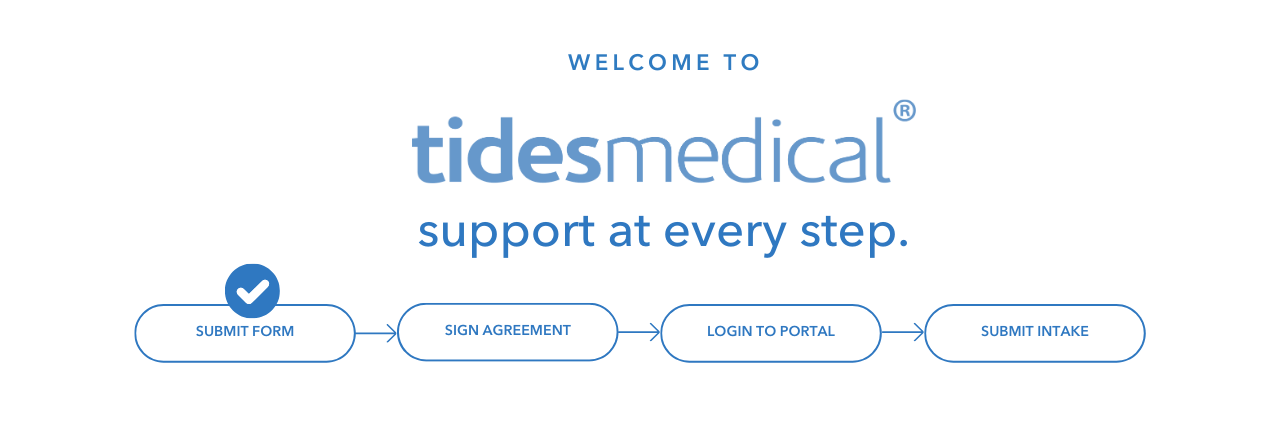

Successful fat harvesting is the first integral step to using your patient’s adipose tissue to create a personalized graft using the Tides Medical APLICOR 3D bioprinting system. When using the APLICOR 3D system, the AiD Regen tablet uses AI to measure the wound bed and calculate the amount of adipose tissue needed from the fat-harvesting procedure.

The Fat Harvesting Procedure

First, the area chosen is numbed, and a small incision is made. Then, a tumescent cannula (a long, blunt-tipped needle) injects a solution into the targeted area to prep the area for the harvesting cannula, which suctions the desired amount of fat. About three times more than the AiD Regen tablet says is needed will be harvested because not all the transferred fat will survive. Typically, about one-third does, compensating for the loss and allowing the surgeon to achieve the desired amount needed for the graft. The incision is then closed with a suture lasting 5-7 days. Once the fat is removed, it is processed using a series of micronizers into a bio-ink, which is used to create a personalized graft using a 3D bioprinter.

Bio-Ink for Skin Grafts and Wound Treatment

Traditional skin grafts often rely on donors, but bioprinting has opened new possibilities for producing customized skin grafts for the patient. With bio-ink derived from fat cells, 3D bioprinting can create skin matching the patient’s biology. This is particularly useful in cases where large areas of skin need to be treated, such as after severe burns or other traumatic injuries.

Until now, Tides Medical products were focused on our specialty: amniotic tissue grafts from the donated placenta of mothers who met the correct criteria. With the launch of APLICOR 3D, we have entered the future of wound care technology. APLICOR 3D is a hyper-personalized tissue regeneration system that utilizes a patient’s adipose tissue to 3D print a customized wound graft. This groundbreaking technology marks a shift in our product offerings, allowing us to include more than our highly regarded amniotic tissue products. We are excited to bring a new level of innovation to the field of wound care.

To learn more about the process of how it works and its benefits, view our previous post, “Introducing APLICOR 3D: Revolutionizing Personalized Medicine with Hyper-Personalized Tissue Regeneration.”

If you need more hands-on training or want to know more about APLICOR 3D, contact Tides at customerservice@tidesmedical.com or visit tidesmedical.com/aplicor-3d.

Conclusion

As we look toward the future, integrating fat harvesting into bio-ink production will continue to play a pivotal role in advancing bioprinting technology, providing innovative treatment options for those needing customized skin grafts. With this new frontier in personalized medicine, patients can hope for better outcomes, reduced recovery times, and a more seamless treatment process, all thanks to the power of 3D bioprinting and bio-ink.

Sources:

https://pmc.ncbi.nlm.nih.gov/articles/PMC6439477/

https://pmc.ncbi.nlm.nih.gov/articles/PMC11153344/

Other sources: Tides, Marketing materials, harvesting video, & Press Release.

Marc Stemler, Ph.D.,

Marc Stemler, Ph.D.,  Mora Melican, Ph.D., VP of Operations, Research & Development

Mora Melican, Ph.D., VP of Operations, Research & Development LESA CATALON,

LESA CATALON, DAVID CASTILLE,

DAVID CASTILLE,

Dr. Thomas E. Serena MD FACS FACHM MAPWCA

Dr. Thomas E. Serena MD FACS FACHM MAPWCA JOSH WILLETT,

JOSH WILLETT, JEFF MONTGOMERY,

JEFF MONTGOMERY, MIKE RIDDLE,

MIKE RIDDLE, BENJAMIN KIMBALL,

BENJAMIN KIMBALL, DOUG PAYNE,

DOUG PAYNE, JOE SPELL,

CEO

JOE SPELL,

CEO